This year, Ateliers deMonaco has introduced a new model to its prestigious Admiral Chronographe Flyback collection; the Prato. The pieces – launched in March of this year – were presented as the fruit of the brand’s new partnership with Prato Automobiles. Further completing the collection, is a new timepiece in rose gold. A standout piece that asserts the brand’s luxurious standards and passion for mechanics.

An ideal partnership

If two worlds were made to collide, watchmaking and automobiles were the ideal candidates.

The two industries definitely echo each other on many levels – precision, a care for detail and a smart design are just a few mere examples. It is therefore no surprise that Ateliers deMonaco and Prato Automobiles came together in an effort to bring their ideals into a series of fine timepieces.

A rose gold marvel of mechanics and aesthetics

An addition to the chronographs released earlier this year, Ateliers deMonaco’s rose gold newcomer needn’t envy its predecessors.

Its shiny 18K rose gold polished case houses the brand’s automatic hand-decorated dMc-760 caliber – the heart of the patented Flyback complication which offers its wearer, a single gesture to go from one measurement of time to another. Protecting this complex mechanical core, a delicate carbon fiber and 18K rose gold dial. Thanks to a specific technique often used in the automotive industry, each dial is meticulously finished and, more importantly, unique.

A face further enhanced by black PVD treated applied roman numerals and the Prato logo.

Finally, the counters and Dauphine hands complete the timepieceoffering a powerful and playful contrast with the rich, textured dial.

Savoir-faire

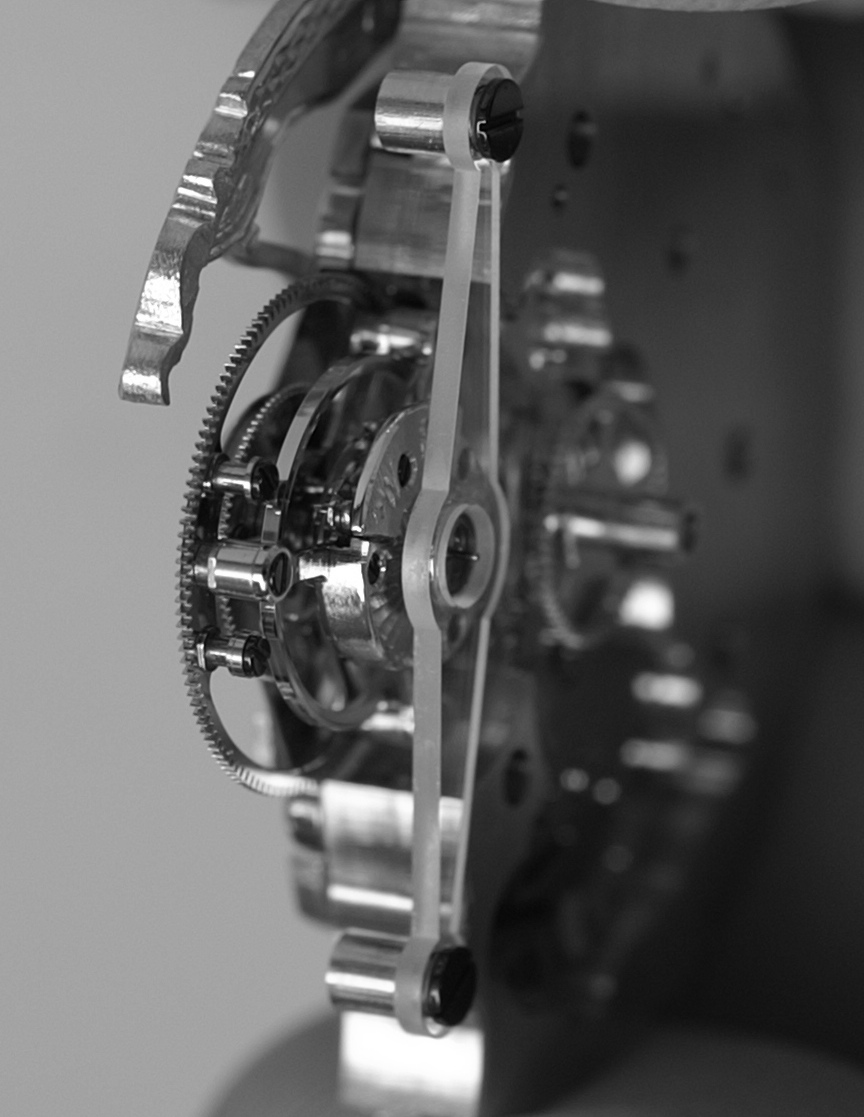

Because beauty should come from within, Ateliers deMonaco takes pride and patience in preparing its components and assembling its movements. The dMc-760 makes no exception to the rule.

The in-house caliber is composed of 226 components split in two essential parts. The first is the base movement, intended to bring to life the hours, minutes and seconds of the watch. The second is the module carrying the flyback chronograph mechanism, which relies on 96 components.

The movement is assembled by hand by the brand’s skilful watchmakers, a long and delicate process which requires both experience and finesse.