Ateliers deMonaco and Prato Automobiles, partners since November 2017, share the same requirement for precision and high level performance. The two brands come together with their common values represented by audacity, a sense of aesthetics, the quest for performance, the constant search for innovation, craftsmanship, technology and know-how. Automobile enthusiasts generally have a strong interest in precious timekeepers and vice versa. In both environments, extreme precision and sporty elegance play an important role. To date, we are launching two new models in the Admiral Chronographe Flyback named “Prato”.

Prato Automobiles X Ateliers deMonaco

The collaboration between Prato Automobiles and Ateliers deMonaco began six months ago with the launch of the Orage motorcar and the Tourbillon Oculus 1297 Orage watch.

The watch includes a microchip inside its strap that allows to open and start the engine of the vehicle. Thus, the Tourbillon Oculus 1297 Orage timepieces are reserved only for the elite owners of the Orage automobiles.

This year, our two Prato models are open to everyone. The unique design inspired by modern sports cars is head-turning and perfectly embodies the identity of the Orage motorcar. It’s a modern testimony to adrenaline and chills of racing.

Flyback chronograph function

The classic chronograph allows us to measure the time of a given action. Thanks to the flyback function, all you need is a single gesture to go from one measurement of time to another. Indeed, it is no longer necessary to stop, reset and restart the chronograph to measure a succession of events. Just by pressing the “flyback” button at 4 o’clock to measure two successive time intervals. This function makes it possible to have a much more precise measurement and simplicity of use.

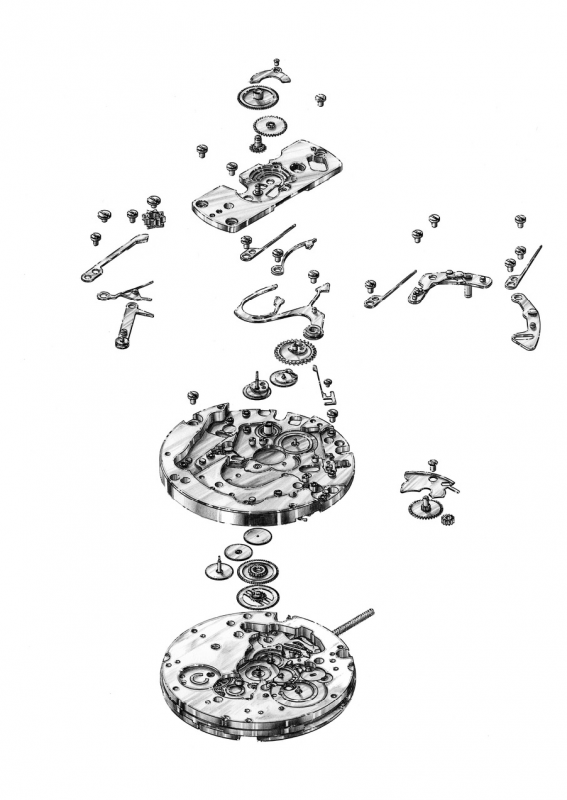

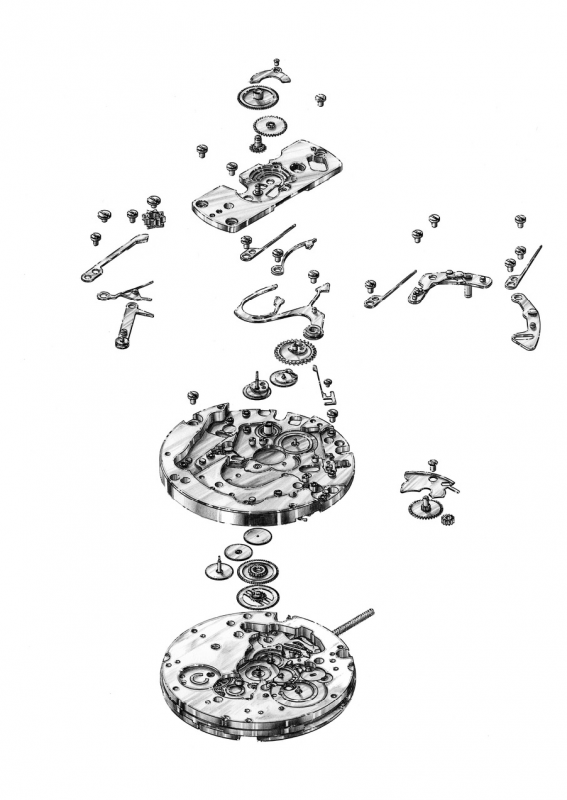

A patented Flyback mechanism called “direct return to zero”

The dMc-760 manufacture caliber comprises 226 components split between two main parts. The first is the base movement, intended for the hours, minutes and seconds functions. The second is the module that features the flyback chronograph mechanism, which is composed of 96 components.

In order to always gain in efficiency, our watchmakers have developed a patented system called “direct return to zero”. This instantaneous flyback system is in fact the simplification of a succession of events. Instead of working successively, our system functions directly which means: Pressing the pusher just once, starts the timer again from zero. In this case, the pusher at 4 o’clock and its associated mechanism causes three tasks to be performed very quickly one after the other: First, the clutch is disengaged; secondly, the chronograph is reset to zero by means of the single-piece hammer, whose sloping surfaces turn the two zero reset hearts so that the hands reposition themselves vertically; and thirdly, the clutch engages once more as soon as the pusher is released. The sequence of movements involved in this action proceeds directly from the pusher to the clutch lever.

A design developed in collaboration with Prato Automobiles

The Admiral Chronographe Flyback collection is expended with two new models called Prato which are inspired by the Orage motorcar. The first, more classic, features a polished steel case, dauphine hands and two silver-colored counters contrasting a black carbon dial mixed with 18-carat white gold. The second, more sporty, has a black DLC steel case, dauphine hands and two rose gold color counters complementing a black carbon dial mixed with 18-carat rose gold. For both versions, Roman numerals are polished, curved, applied and treated with black PVD. The dials are adorned with the logos of “deMonaco” and “Prato”.

A steel case Armure

With the desire to always use state of the art techniques, the 42mm case is treated with a process called Armure that allows steel to be about five times more scratch resistant than ordinary steel. Indeed, it is treated with a chemical process of diffusion of carbon at low temperature which hardens the surface of the steel. From 220 Vickers to 1200 Vickers. This case is both exceptionally ergonomic and comfortable to wear.

An innovative dial

The dials of the two Prato models are inspired by a technique used in the automotive industry called forged carbon. We developed a new method that includes 18-carat gold in the process. This is the first time ever in watchmaking history that such a dial is created. To achieve this result, carbon fiber, gold and resin must be mixed and placed in a mold. Then, this mixture is heated and pressed to fix everything and form a block. Thanks to this technique, each dial is unique. After the molding process, each dial is meticulously refined to achieve the perfect shape.